Background: The Korean Association of External Quality Assessment Service provides proficiency test (PT) materials through a logistics company. We investigated the delivery times of PT materials in 2020 and the methods to reduce delivery delay. We also attempted to prolong the proper storage temperature with the addition of ice pack.

Methods: The lead times of deliveries from 2020 were calculated. We also checked the duration for which 600 g×6 packs of dry ice or 24×16 cm ice gel packs could maintain the proper temperature. To reduce delivery delay, the delivery day for HbA1c testing material was changed from Monday to Tuesday. To prolong the duration of proper temperature maintenance for cold shipping, an extra 12×17 cm ice gel pack was added.

Results: The average delivery time was 23 hours, 5 minutes, and 12 seconds (min–max: 17:9:8–84:31:39). The average delivery delay rate was 2.81% (min–max: 0.23%–11.25%). The delay rate for shipping on Monday was 11.25%; changing the delivery day to Tuesday reduced the delay rate to 1.76%. The addition of a 12×17 cm-sized ice gel pack along with the 24×16 cm gel pack prolonged the duration of proper storage temperature maintenance for cold shipping by 6 hours.

Conclusions: Shipping on Tuesday instead of Monday can be an effective option to reduce the delivery delay rate, and the addition of a 12×17 cm ice gel pack can prolong the proper cold shipping temperature.

Keywords: Proficiency test materials, Sample stability, Delivery delay rate, Storage temperature range

서론

현재 대한임상검사정도관리협회는 외부정도관리를 목적으로 신빙도조사사업을 시행하고 있으며, 매해 신빙도조사물질을 참가기관에 배송하고 시행된 검사결과를 분석함으로써 검사의 정밀도와 정확도를 높이기 위해 노력하고 있다. 신빙도조사물질은 택배회사를 통해 배송되며, 2019년에는 약 1,820여 개의 참가기관에 총 8차에 걸쳐 물질이 배송되었다. 신빙도조사물질을 빠른 시간 내에 배송하는 것은 신빙도조사사업의 가장 중요한 부문 중 하나일 것이다. 배송이 지연되면 신빙도조사물질을 적정 보관온도에 배송하기 위하여 함께 동봉한 보냉물질이 녹아서 물질이 적정 보관온도를 벗어날 수 있고, 물질이 변질되어 검사결과에 영향을 끼칠 수 있기 때문이다.

대한임상검사정도관리협회는 홈페이지 게시판을 통해 각종 인증사업과 신빙도조사사업에 대한 문의를 접수하고 있다. 또한 배송과정 중 발생할 수 있는 물질 이상이나 배송 지연에 관련한 게시글을 접수하여 대응함으로써 신빙도조사사업의 개선을 도모하고 있다.

본 연구에서는 대한임상정도관리협회가 신빙도조사사업 참가기관에 물질을 안정적으로 배송할 수 있도록, 배송 소요시간을 조사하고 배송 지연을 감소시키기 위한 방안을 모색하고자 하였다. 또한 배송 지연이 불가피할 경우, 운송 시 적정 온도를 유지하기 위한 방안을 마련하고자 하였다.

재료 및 방법

1. 신빙도조사물질 배송시간 관리

1) 신빙도조사물질 배송시간 파악2020년에 총 8차의 배송이 예정되었으며, 신빙도조사사업 참가기관에 물질이 도착된 상세내역을 택배회사로부터 전달받아 배송 소요시간을 파악하였다. 또한 배송 중 보관에 영향을 끼칠 수 있다고 예측되는 중요 시점에 따라 배송시간을 4개 시간 구획으로 나누었다(Table 1).

Table 1 . Breakdown of lead time at which proficiency test materials were delivered.

SectionLead time (hr)| Section 1 | 27 hours after shipping (after 1 day, before 6 PM) |

| Section 2 | 27.01–41.00 (after 2 days, before 8 AM) |

| Section 3 | 41.01–51.00 (after 2 days, before 6 PM) |

| Section 4 | >51.01 (after 2 days, after 6 PM) |

2) 배송 지연비율 감소 위한 방안 모색

실험을 통하여 냉동과 냉장 배송의 각 경우에 보냉물질이 모두 소모되어 배송상자 내 온도가 물질의 적정 보관온도인 –70℃– –20℃ 또는 2℃–8℃ 이상으로 상승하는 시간을 측정하여, 이를 배송 지연의 기준시간으로 책정하였다. 실험은 온도 23℃–27℃가 유지되는 실내에서 시행하였으며, 실제 배송 시와 같이 냉동 배송조건으로 드라이아이스 600 g×6개 그리고 냉장 배송조건으로 중형 아이스겔(24 cm×16 cm) 1개를 넣은 배송상자 각각 1개에 온도 로거(Tempod 100× Data logger; TempSen Electronics, Shanghai, China)를 동봉하였다. 온도 로거 동봉 외 드라이아이스나 아이스겔의 종류나 개수 등 연구에 기인한 변경사항은 없었다.

신빙도조사물질은 통상 일요일에 택배회사에서 수거하여 배송이 시작된다. 그러나 HbA1c 물질이 포함되어 있는 2차와 8차 배송 시, 공여자가 평일에 물질 제조기관에 내원하여 채혈 후 물질이 제작되기 때문에 월요일에 배송이 시작된다. 택배회사와 논의결과, 월요일은 일반택배 물량이 많아 신빙도조사물질의 배송 또한 지연될 확률이 높다는 것이 추정되어, HbA1c 물질이 포함된 2020년 8차 배송 시에는 화요일에 배송하는 방안을 시도하였다. 또한 배송시간을 단축시킬 수 있는 다른 운송방법을 조사하였다.

2. 물질 배송과정 중 온도 관리

1) 배송과정 중 온도 파악(1) 냉동 배송과정의 온도

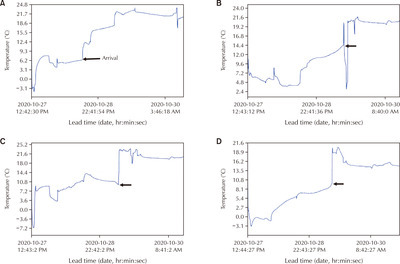

2019년 배송 상세내역을 살펴볼 때, 일반적으로 제주도 등 도서산간지역 참가기관의 배송 지연이 많았던 것이 확인되었다. 따라서 제주도 소재 참가기관 4곳을 무작위로 선정하여 신빙도조사물질과 함께 온도 로거를 동봉하여 배송 시 온도를 확인하였다. 2020년 7차 배송은 냉동 배송 회차로 드라이아이스 600 g×6개와 함께 온도 로거를 동봉하였다.

(2) 냉장 배송과정의 온도

8차 배송은 냉장 배송 회차로 냉동 배송과정의 온도 확인 때와 같이 제주도 소재 4개 참가기관에 중형 아이스겔과 함께 온도 로거를 동봉하여 배송 중 온도 변화를 확인하였다.

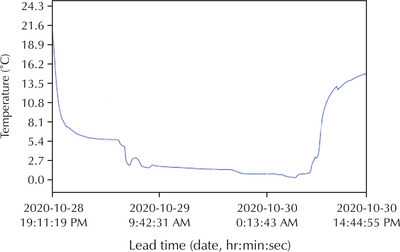

2) 적정 온도 유지 위한 방안 모색배송이 지연되어도 최대한 적정 보관온도를 유지하기 위하여 보냉물질의 개수를 추가하는 방안을 시도하였다. 기존 신빙도조사물질 배송 시 동봉되는 중형 아이스겔을 배송상자 1개에 넣고 소형 아이스겔(12 cm×17 cm)을 1개 추가하여 실험을 시행하였다.

결과

1. 신빙도조사물질 배송시간 관리

1) 신빙도조사물질 배송시간 파악신빙도조사물질의 평균 배송시간은 23시간 5분 12초(최단–최장: 17시간 9분 8초–84시간 31분 39초)였다(Fig. 1). 배송 후 27시간(구획 1) 내에 평균 94.08%의 기관에 배송이 완료되었고, 27.01–41.00시간(구획 2)과 41.01–51.00시간(구획 3), 그리고 50.01시간 이후(구획 4)에 배송이 완료되는 기관의 평균 비율은 각각 2.79%, 2.55%, 그리고 0.58%이었다(Fig. 2). 51.01시간을 초과(구획 4)하여 물질이 배송되는 기관 중에는 도서지역의 기관이 대부분이지만, 택배회사의 오류로 인해서 배송이 지연되는 경우가 매 회차당 최소 2기관 이상 포함되어 있었다.

2) 배송 지연비율 감소 위한 방안 모색

냉동과 냉장 배송 시 배송상자 내부 온도가 적정 보관온도 이상으로 상승하는 시간은 각각 46시간과 36시간이었다(Fig. 3). 이러한 배송 지연 기준점을 바탕으로 계산한 전체 회차의 배송 지연비율은 평균 2.81%(최저–최고: 0.23%–11.25%)였다(Table 2). 냉동과 냉장 배송의 평균 배송 지연비율은 각각 2.58%(최저–최고: 0.23%–4.92%)와 2.88%(최저–최고: 0.69%–11.25%)였다. 일요일에 배송된 회차의 평균 배송 지연비율은 1.57%(최저–최고: 0.23%–4.92%)였고, 월요일에 배송된 2차 배송 시 배송 지연비율은 11.25%로 가장 높았다. 배송 지연을 감소시키기 위하여 화요일에 배송된 8차 배송에서는 배송 지연비율이 1.76%로 감소하였다.

Table 2 . Delivery delay rate for each challenge (%).

1st2nd3rd (frozen)4th5th6th7th (frozen)8thAverage| Delay rate | 0.69 | 11.25 | 0.23 | 1.22 | 1.39 | 0.99 | 4.92 | 1.76 | 2.81 |

배송 지연비율을 감소하기 위해 항공택배를 사용하는 방안을 살펴보았을 때, 제주도 항공택배의 경우 1개의 참가기관당 10만 원의 배송료가 소요되어 비용 상승의 문제가 발생하며, 배송 지연이 종종 발생하는 연평도나 목포 등의 기관에는 적용할 수 없다는 제한점이 있었다. 우체국 익일 특급의 경우, 크기 30 cm×23 cm×26 cm의 배송상자 전체를 우체국에 직접 운송하여 접수시켜야 하는 조건이 있어 적용하기에 제한점이 있었다.

2. 물질 배송과정 중 온도 관리

1) 배송과정 중 온도 파악(1) 냉동 배송과정의 온도

2020년 7차 배송은 2020년 10월 11일에 시행되었으며, 기상청 보고에 의하면 2020년 10월 11일부터 15일까지 전국의 온도는 12.3℃–26.1℃에 분포하였다[1]. 제주도 소재 4개 참가기관의 담당자로부터 물질 수령 후에도 드라이아이스가 남아 있음을 확인하였으로, 배송과정 중 온도는 –68.1℃에서 –20.6℃로 유지되었다(Fig. 4). 평균 배송시간은 38시간 23분 47초(최단–최장: 27:32:36–42:29:09)였다.

(2) 냉장 배송과정의 온도

2020년 8차 배송은 2020년 10월 27일에 시행되었으며, 2020년 10월 27일부터 31일까지 전국의 온도는 17.4℃–22.9℃에 분포하였다[1]. 제주도 소재 4개 참가기관의 담당자 모두로부터 물질 수령 시 아이스겔은 모두 녹아 있었음을 확인하였다. 배송과정 중 온도는 2.0℃–15.3℃에 이르며, 평균 배송시간은 39시간 15분 42초(최단–최장: 27:01:35–44:56:32)였다. 4개 기관 중 1개 기관에서는 27시간 만에 물질을 수령하였으며, 배송 완료 시까지 상자 내 온도는 8℃ 미만으로 유지되었지만, 배송에 40–44시간이 소요된 3개 기관에서는 평균 36시간이 지나면 8℃ 이상으로 상승하기 시작하여 최고 15.3℃에 이르렀다(Fig. 5).

2) 적정 온도 유지 위한 방안 모색

제주도 소재 4개 기관에 냉동 배송 시 42시간이 넘어도 배송박스 내부 온도가 –20℃ 이하로 유지되었기에 추가적 방안은 시도하지 않았다. 냉장 배송 시, 배송상자 내 온도 유지시간을 연장하기 위하여 기존 중형 아이스겔과 함께 소형 아이스겔 1개를 추가한 결과 포장상자 내부 온도는 42시간가량 8℃ 내로 유지되어 6시간가량 더 오랫동안 온도 유지가 가능하였다(Fig. 6). 소형 아이스겔을 2개 추가하였을 때에는 상자 내부 온도가 3시간 이상 영하로 내려간 상태로 유지되었기 때문에 물질의 용혈이 발생할 가능성이 있어 더 이상 실험을 진행하지 않았다.

고찰

일반적으로 상품화된 신빙도조사물질의 냉동 보관조건은 –70℃에서 –20℃이며, 냉장 보관조건은 2℃–8℃이다[2,3]. 대한임상검사정도관리협회의 신빙도조사물질을 적정 보관온도를 유지한 상태로 안정적으로 배송하기 위하여 배송 소요시간을 관리하고 배송이 지연되는 기관의 비율을 감소시키고자 하였다.

냉동과 냉장 배송에 대한 각각의 배송시간을 확인한 뒤, 보냉물질이 모두 녹아서 배송상자 내부 온도가 적정 보관온도 이상으로 상승하는 배송 지연 기준점을 바탕으로 계산했을 때 평균 2.33%(최저–최고: 0.11%–11.26%)에서 배송이 지연되었다(Table 2). 정확도기반 HbA1c 프로그램이 속한 물질 배송 시, 일반 택배 물량이 많은 월요일을 피해서 화요일에 배송했을 때, 배송 지연비율이 11.26%에서 1.71%로 감소함을 확인하였다. 따라서 추후 정확도 기반 HbA1c 물질 배송 시, 화요일에 배송을 시행한다면 배송 지연비율을 줄일 수 있을 것이며, 이를 통해 적정 보관온도를 유지한 상태로 배송 될 수 있는 확률을 높일 수 있을 것으로 판단된다.

택배사의 오류로 인한 경우와 도서산간지역의 참가기관의 경우 불가피하게 배송이 지연될 경우가 발생하기에, 배송 중 배송상자 내 온도 변화를 확인하고, 최장 시간 동안 물질의 적정 보관온도를 유지하기 위한 방안을 마련하고자 하였다. 냉동 배송의 경우 평균 46시간까지 –20℃ 이하로 유지되어 평균 0.64%에 해당하는 소수의 기관에만 배송 지연이 발생할 것으로 예상되며, 배송상자의 공간이 제한되어 있어 추가적인 드라이아이스의 적재가 불가능하여 추가적인 방법은 고려하지 않았다. 냉장 배송 시는 기존의 중형 아이스겔만 사용 시 36시간 가량 2℃–8℃로 유지되어 평균 2.89%의 기관에 배송이 지연되었다. 반면, 소형 아이스겔을 추가하면 42시간까지 8℃ 내로 온도가 유지되어, 평균 0.55%(최저–최고: 0.10%–1.82%)로 배송 지연비율을 감소시킬 수 있을 것으로 판단되었다.

대한임상검사정도관리협회의 신빙도조사물질의 배송시간을 관리하고 이에 따른 온도 변화를 관리하는 것은 신빙도조사사업의 가장 중요한 부분 중 하나일 것이다. 냉동 배송 시에는 현재의 방법을 유지할 때, 99.36%에 해당하는 기관에 안정적으로 신빙도조사물질을 배송할 수 있을 것으로 예측되며, 냉장 배송 시에는 소형 아이스겔을 추가하는 방법을 적용한다면 기존의 97.11%에서 최대 99.45%의 기관에 안정적으로 신빙도조사물질을 배송할 수 있을 것으로 판단된다.